PLASTIMO COMPASSES: 40 YEARS ON THE RIGHT COURSE

For ultimate quality, Plastimo selects the best components in order to ensure that your compass is a highly dependable instrument which will provide years of reliable service. For ultimate quality, Plastimo selects the best components in order to ensure that your compass is a highly dependable instrument which will provide years of reliable service.

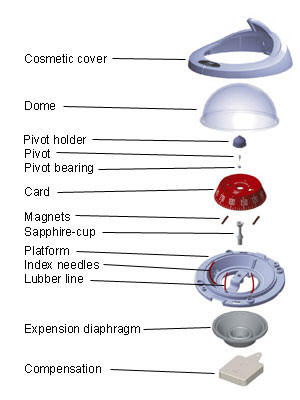

- Sapphire bearings are at the heart of every Plastimo compass. Their hardness is a guarantee of the long life and precision of your compass.

- All Plastimo compasses feature an anti-vibration system, which ensures minimal contact between the pivot and the sapphire cup; the "Vibration absorber" device damps spinning caused by high-speed pounding and vibration

- A compass is a meticulously engineered instrument: all the "precious" components are produced by Swiss clock-makers, famous worldwide for their legendary precision.

- The soft Viton« diaphragm or the semi-soft ultra-sound welded diaphragm is fully waterproof and has an extreme expansion and retraction capacity: it compensates for fluctuations in fluid volume caused by the differences in temperature and atmospheric pressure.

- All plastic components -more specifically the material used for the dome- are carefully selected to withstand shocks, UV-rays and harsh marine environment.

- The crystal transparency of the dome and the exceptional magnifying index of the fluid contribute to the perfect legibility of the card.

To be allowed on your boat, a Plastimo compass must pass challenging quality control tests

Needless to say, all Plastimo compasses comply with the regulationàbut Plastimo's stringent requirements are even more demanding: at every stage of production, each compass is tracked, checked and thoroughly inspected, so that quality is never a coincidence.

- Accelerated ageing tests, carried out in Plastimo laboratories, guarantee that the dome and all other components are totally impervious to UV rays.

- Vibration tests used to simulate the vibrations generated by rough sea and high-speed: the card must remain absolutely stable, whatever the vibration frequency. While the regulation requires tests from 7 to 40 Hz, Plastimo challenges its compasses to tests between 5 and 100 Hz.

- Temperature tests: Plastimo compasses are tested in heated and refrigerated cabinets from +60? to -20?C (+140? to -4?F). Even in these extreme temperatures, the compass must not leak or develop bubbles.

- Stability tests: when the card is deflected (40? or 90?), it must return to its original position and settle within a predetermined time (called the "half-period").

- Precision and accuracy are tested on each cardinal point. After a 95? deflection, the card must return to its original position, within a 1? maximum allowance.

- Packaging protection: in order to guarantee optimum protection during transport, we regularly drop test Plastimo packaged compasses from a 1 metre height to a hard surface.

- Final quality tests: assembled, packaged and ready for shipment, Plastimo compasses are once again inspected with a statistical sampling.

|